| Sign In | Join Free | My chinaqualitycrafts.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinaqualitycrafts.com |

|

Brand Name : Yucera

Model Number : 5 Axis CAD CAM Milling Machine

Certification : CE/ISO

Place of Origin : China

MOQ : 1 piece

Price : negotiation

Payment Terms : negotiation

Supply Ability : 20000pcs/month

Delivery Time : 15 days

Packaging Details : 1 piece for one package

Main axis speed : 0-60,000rmp

Size of CNC machine : 55*56.5*46cm

Size of Host milling machine : 45*25*45cm

Gross weight : 148Kgs

Cutting precision : 0.02mm

Name : SK-5A dental milling machine

Usage : milling dental zirconia blocks/pmma

Service : online technical supporting

Total power : 800W

Tool magazine capacity : 5

Processing methods : Five-axis linkage,dry milling

Dental Milling Machine Cad Cam Dental Zirconia Block SK-5A 5axis Milling Machine

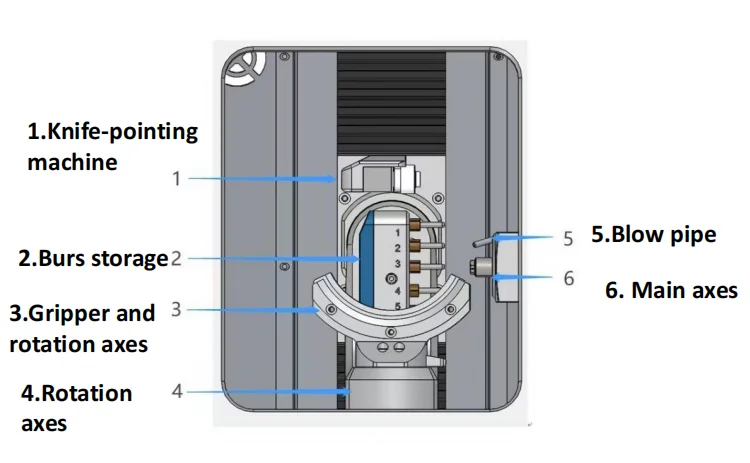

Detailed Product Description of dentai milling machine SK-5A:

| Name | Yucera SK-5A dental milling machine |

| weight | Cutting machine:95KG Main engine:20KG |

| Rotating axis operating angle | A:360° B:±30° |

| Cutting precision | 0.02mm |

| Tool magazine capacity | 5 |

| Main axis speed | 0-60,000rmp |

| Processing methods | Five-axis linkage,dry milling |

| Total power | 800W |

Advantages

1.Split type machine; easy to maintain, reduce the damage of dust to the main engine,;and prolong the service life of the machine

2.Horizontal machine, lower center of gravity, strong stability; processing speed increased by 20%

3.Improved fixture , the utilization rate of zirconium block is increased by 30%; 38-40 units of crown/bridge can be cut at one time

Cleaning and maintenance after processing for 5 axis cadcam milling machine

Check the dust system regularly, preferably for two to three days, insert the trachea pipe into the hole behind the vacuum cleaner, press the dust key and suck.

Usage

1.Our product can milling

Zirconia blocks

PMMA

Wax

Composite material

2. support cad cam milling

Equipment maintenance

1.Regular cleaning:Use a suitable liquid detergent to clean the plastic part,and be careful not to use an air gun to clean the Interior to prevent dust and debris from entering the mechanical parts.

2.Material fixture cleaning:Clamps and screws should be kept clean when placing material for optimum grip

3.Main Axis Clip Cleaning:Do not spray oily spray or compressed air containing oil and water directly on the spindle head; The spindle chuck and bur must be clean.The entry of impurities can cause processing failures

|

|

Denture 800w 5 Axis Dental Milling Machine 0.02mm Precision Images |